When it comes to your roofing project, one of the critical decisions you’ll need to make is choosing the right underlayment or felt. Traditionally, there were two main options: 15-pound felt and 30-pound felt. However, in recent times, synthetic underlayment, sometimes referred to as synthetic felt, has emerged as an alternative choice.

To make an informed decision, it’s best to compare these types of felt in two separate sets: synthetic vs. felt underlayment, and if you opt for felt, the comparison between 15-pound and 30-pound options. This approach provides a clear understanding of the differences and helps you choose the right underlayment for your roofing project.

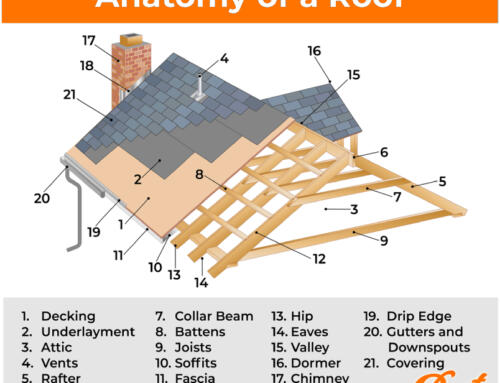

Understanding Underlayment Options

Before diving into the comparisons, it’s crucial to have a clear understanding of the various underlayment options. Both felt and synthetics are types of roofing underlayment that serve several essential functions:

- Water Protection: Underlayment provides an additional layer of protection in case water penetrates the shingles on the roof. It prevents moisture from reaching the inner structure and decking, especially during roof installation or repairs.

- Enhanced Fire Rating: Underlayment can improve your home’s fire rating, offering an added layer of safety.

- Worker Safety: It also provides roofers with slip protection during shingle installation.

Felt vs. Synthetic Underlayment

Let’s begin by comparing asphalt felt (traditional felt) as a general category with synthetic underlayment:

Perm Rating

One significant difference between the two is the perm rating. Synthetic underlayment often has a lower perm rating than felt, making it more challenging for moisture within the attic to escape through the roof. Adequate attic ventilation is crucial for both, but it becomes especially crucial with synthetic underlayment.

Price

The cost of your underlayment will vary depending on the specific product you choose. Generally, synthetic underlayment tends to be more expensive. The price varies based on factors such as thickness, walkability, and exposure time.

- Heavier synthetics cost more but offer higher performance.

- Thinner synthetics are often comparable in price to high-quality 15-pound felt.

- Some lower-quality synthetics can be cheaper than 15-pound felt.

Roll Sizes

The way underlayment is packaged also differs. Roofing felt typically comes in rolls that are three feet long, covering approximately 400 square feet. In contrast, synthetic rolls are larger, usually covering about 1,000 square feet and measuring about four feet long. Larger synthetic rolls can speed up the roofing process.

Safety

In the past, early synthetic underlayment could be slippery when wet, making felt the safer option. However, modern synthetics frequently have better walkability than felt, although this may vary depending on the specific product.

Weather Resistance

Synthetic underlayment tends to perform better in windy conditions compared to felt, assuming it is properly fastened. It also captures less heat due to its gray color compared to the black color of felt, which can get hot in the sun. Additionally, synthetics have advantages in cold temperatures, as roofing felt tends to become stiffer and curl in lower temperatures.

Weight

Synthetic underlayment is significantly lighter than felt. Ten square feet of felt can weigh around 130 pounds, while an equivalent amount of synthetic underlayment would weigh just 23 pounds. This weight difference makes synthetic underlayment easier to transport and handle during installation.

15-pound vs. 30-pound Felt Underlayment

Now, let’s explore the comparison between the two weights of felt underlayment: 15-pound and 30-pound.

The Main Difference

The primary distinction between the two is the original weight of 100 square feet of the felt. Historically, 15-pound felt underlayment weighed 15 pounds for this amount, while 30-pound felt weighed 30 pounds. Therefore, the 30-pound felt was twice as heavy.

Over the years, advancements in technology have reduced the weight of both types of felt, but the names have remained the same. Today, felt is not only lighter but also has improved tensile strength.

Roof Slope

For roofs with steeper slopes, it’s recommended to use 30-pound felt instead of 15-pound. This is essential due to the 30-pound felt’s increased slip protection and resistance to tearing. Thinner felt on a steep roof is more likely to rip.

Tear Resistance

In general, 30-pound felt is less likely to tear than 15-pound felt. This durability is advantageous during installation, for roof protection, and other functions.

Moreover, if a shingle comes off during a storm, 30-pound felt is less likely to tear along with the shingle, ensuring your roof remains protected. In contrast, 15-pound felt may get torn off, leaving the underlying roof structures exposed.

Thickness and Wear

The greater weight of 30-pound felt also results in increased thickness and better wear over time compared to 15-pound felt.

Current Preferences

Many roofing contractors today prefer to use synthetic underlayment due to its advantages in terms of strength, weight, safety, and cost-effectiveness. However, not all roofing systems are compatible with synthetic felt. In such cases, most contractors recommend 30-pound felt if it fits your budget and project requirements. While 15-pound felt can provide sufficient protection in many cases, both synthetic and 30-pound felt generally offer superior performance.

In summary, your choice of roofing underlayment should align with your specific project requirements, budget, and local climate conditions. Consult with roofing professionals like Best Roof And Gutter to determine the most suitable underlayment for your roofing project.

Booking a Free Estimate and Sharing Your Experience

To kickstart your roofing project and explore your underlayment options, consider booking a free estimate with Best Roof And Gutter through www.bestroofandgutter.com. Their team of experts can provide tailored recommendations based on your needs.

After completing your roofing project, you can contribute to the community by sharing your experience on their social media pages:

Your feedback not only supports a local business but also helps fellow homeowners make informed decisions about their roofing endeavors.

Conclusion

Selecting the right roofing underlayment, whether it’s traditional felt, synthetic underlayment, or a specific weight of felt, is a crucial decision in any roofing project. Each type of underlayment has its advantages and considerations, and the choice should be based on factors like climate, budget, and project requirements.

Modern synthetics offer several benefits but may not be suitable for all roofing systems. In such cases, 30-pound felt underlayment can provide enhanced protection and durability compared to 15-pound felt.

To ensure the success of your roofing project, collaborate with professionals like Best Roof And Gutter who can offer expert guidance tailored to your specific needs. Whether you opt for traditional roofing felt or synthetic underlayment, the goal is to achieve a reliable, long-lasting, and weather-resistant roofing system that enhances the overall quality and value of your home.